TOOL & DIE

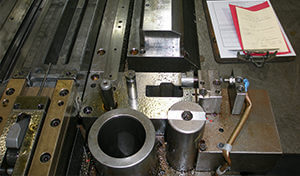

Our comprehensive tool and die services allow you to find all the solutions you need, all in one place! Whether you’re looking for help with design, build, repair or incorporating engineering changes, Titan does it all!

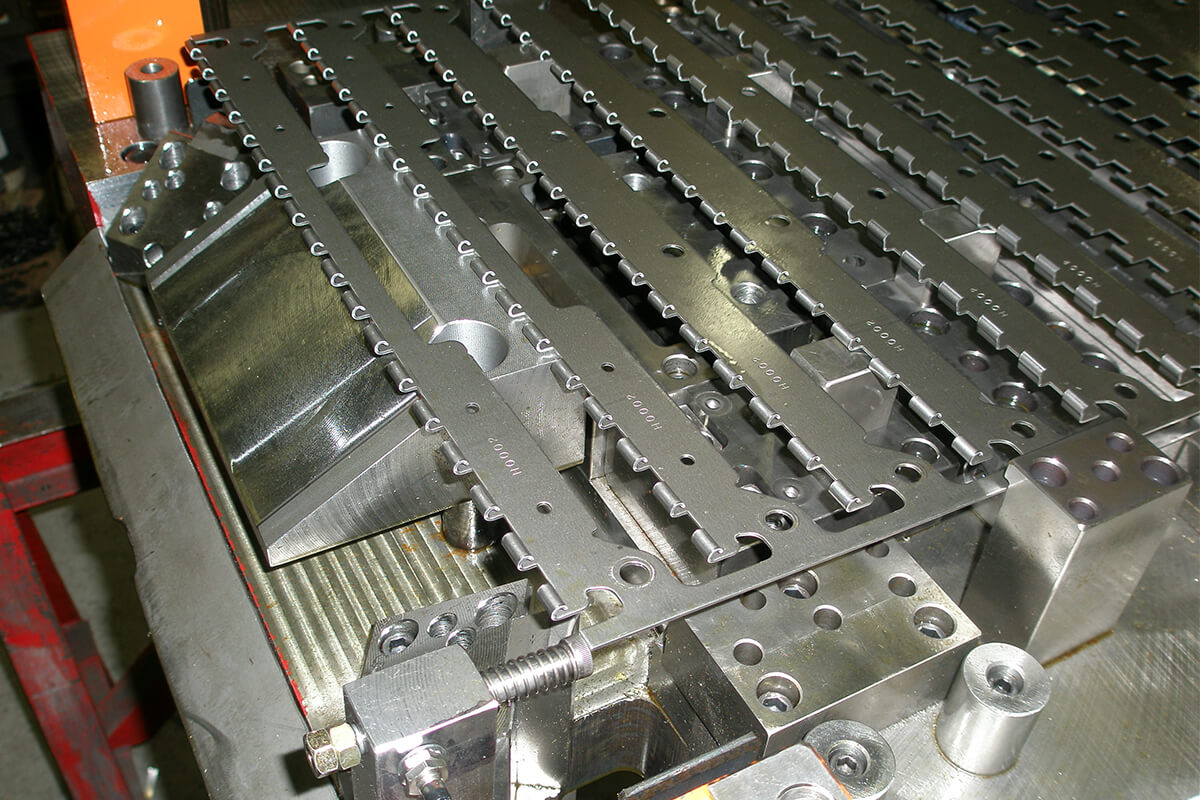

Specialties: Progressive Stamping dies, Line (Hand Transfer) dies, and Pre-pierce / Cut-off dies for roll form parts. We work with most of the latest part materials (Aluminum, Stainless, Dual/Multi-Phase and Martensite!). We also can produce two and three-axis Mechanical or Servo Transfer System Dies, as well as Walking Beam Transfer (both in die and separate) dies and systems.

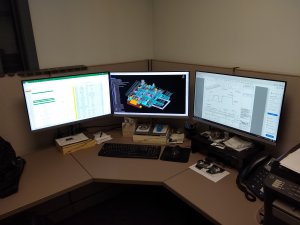

Engineering/Design

Engineering/Design

All designs are done in the latest version of Catia V5 with a complete Bill of Materials. These are kept up to date so as-built copies can be sent after the tool leaves our facility. We work with simulation engineers as necessary using the latest version of Auto Form software. With a background in die automation, we are ready to look at most unique projects intended to streamline production. We offer in-house design reviews, customer location design reviews or web review meetings to expedite the design approval process.

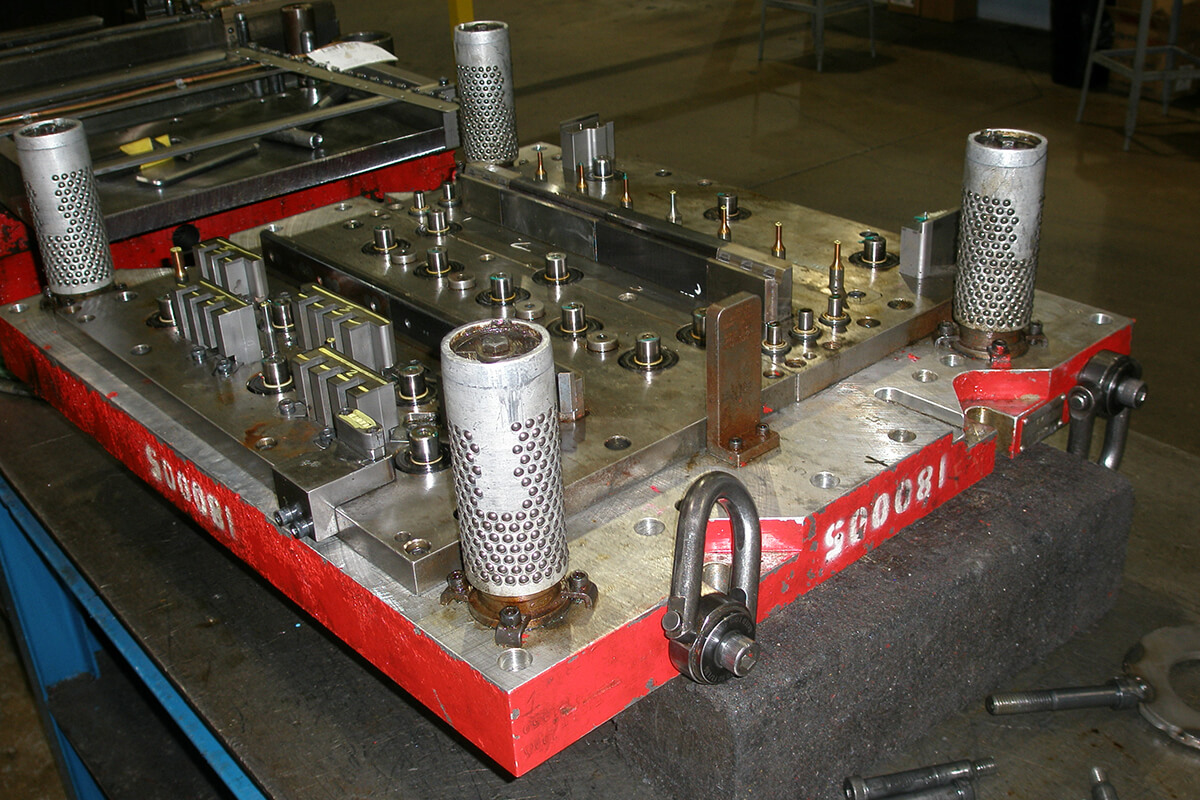

METAL STAMPING DIES

METAL STAMPING DIES

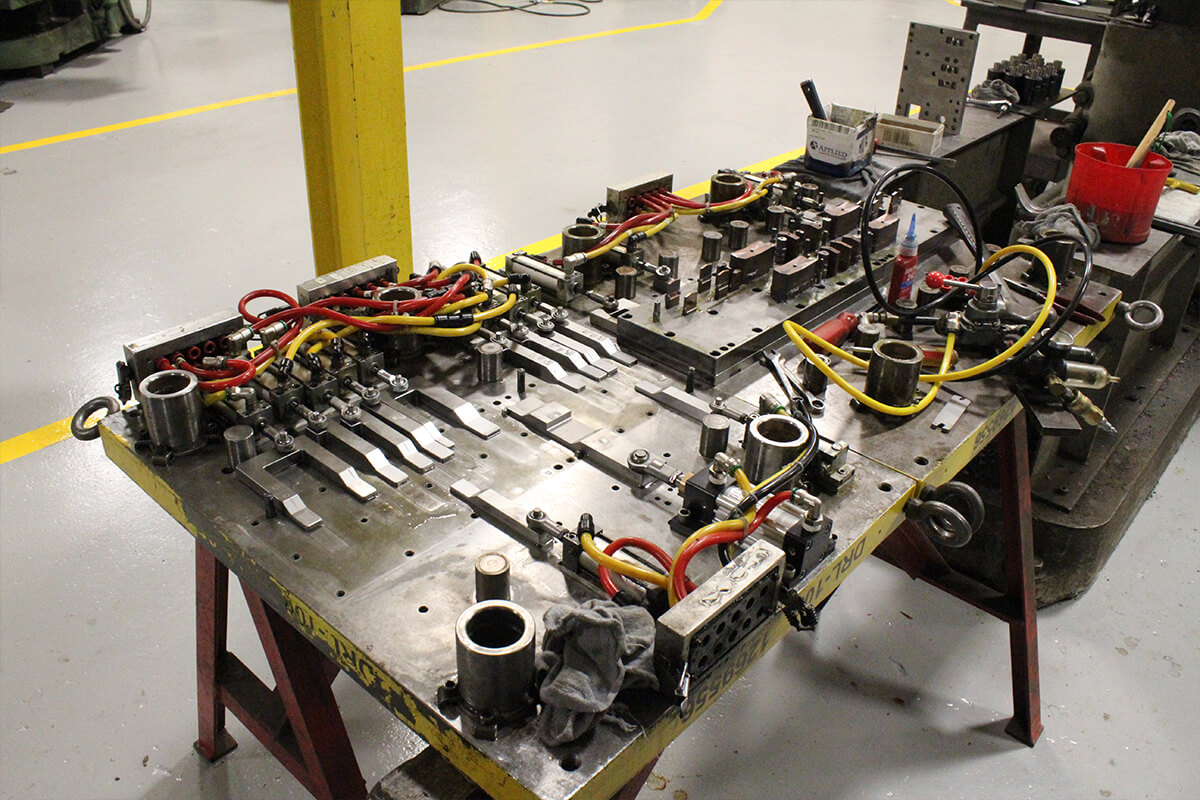

Titan 600-Ton, 400-Ton and 150-Ton tryout presses allow us to Blank, Form, Trim/Pierce and Flange parts per the customer’s requirements (run at rate capability studies) and a maximum tool size of 136" X 83". We provide Line dies, two and three axis Mechanical and Servo Transfer Dies, Blanking dies and Progressive Stamping dies. We have tool try out capabilities to run material that is 48” wide and 0.025” thick with a servo driven feed system to run at production intended rate (cycle time).

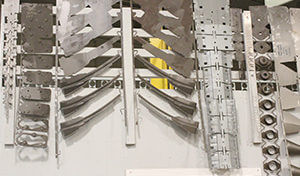

ENGINEERING CHANGES

ENGINEERING CHANGES

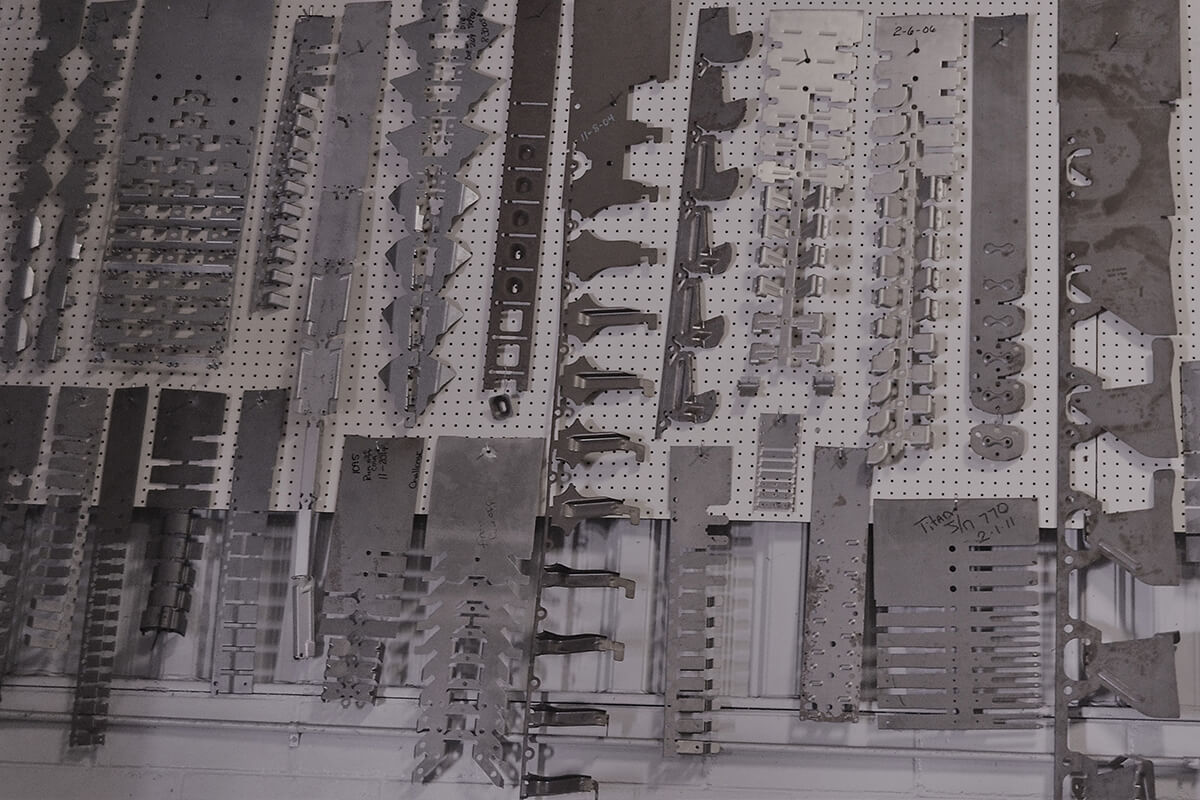

There are times when you may require a die modification to an existing tool. We have the skills to make the necessary changes to the tool through EDM dovetail inserts for trims, wire-burning added button or trim steels, or modifying both trim and form steels. We can meet your needs no matter if it is a tool we built or someone else has built, and we’ll make the changes you require on-time and to print specifications.

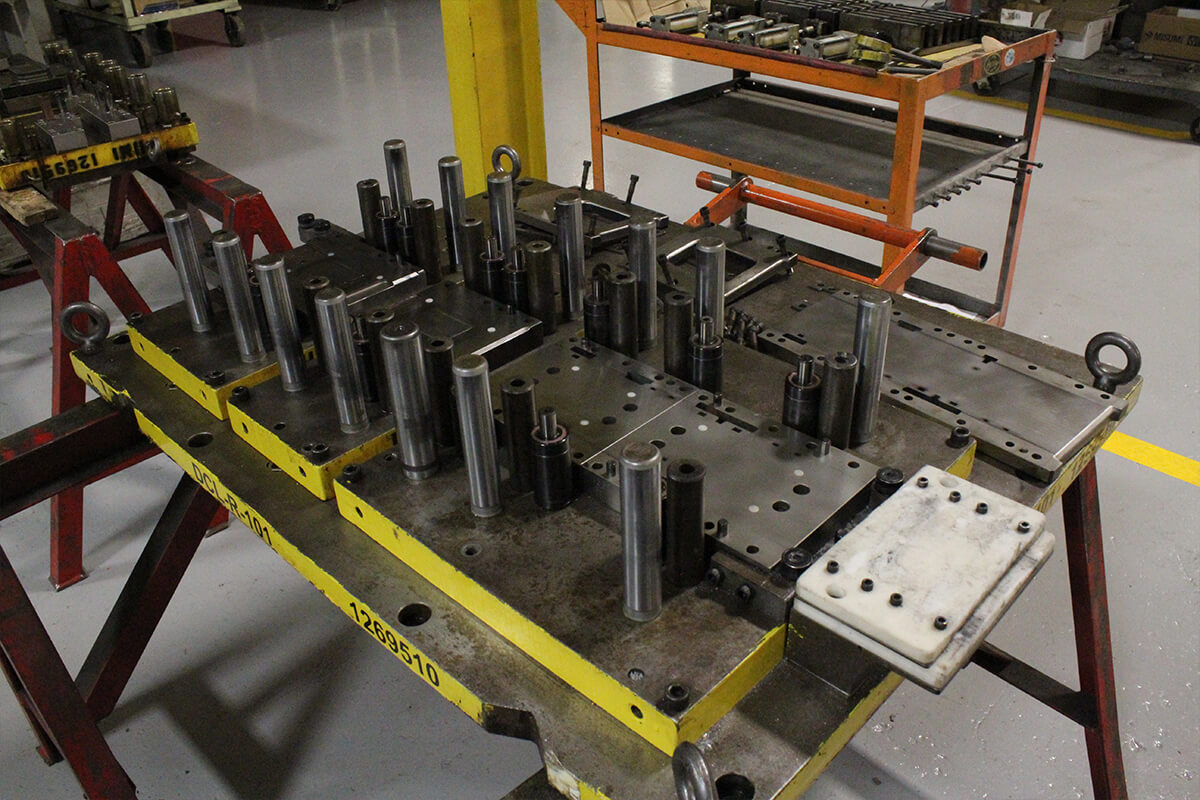

DIE REPAIR

DIE REPAIR

Daily maintenance of dies keeps your operations running smoothly and your costs down. Titan maintenance and repair service can reduce your maintenance costs, not to mention downtime, significantly. We can service dies we built or dies built by others.